Fasteners and Machining: Maximizing Design for Superior Production

Fasteners and Machining: Maximizing Design for Superior Production

Blog Article

Opening the Possible: Fasteners and Machining Solutions for Seamless Procedures

In the elaborate landscape of commercial operations, the function of fasteners and machining options typically goes undetected, yet their significance in ensuring effective and smooth processes can not be overemphasized. The mindful option of fasteners and the usage of accurate machining strategies are crucial in accomplishing a seamless combination that can boost functional efficiency to brand-new elevations. By diving right into the realm of fasteners and machining options, a globe of untapped possibility and improved efficiency awaits those that are eager to check out the possibilities that exist within.

Importance of Choosing the Right Bolts

Choosing the ideal bolts is critical for making sure the structural stability and durability of any setting up. The selection of bolts can dramatically influence the performance and dependability of the end product. By making use of the best bolts, suppliers and engineers can boost the general high quality of the setting up and lower the threats of failing or early wear.

When choosing bolts is to match the product of the bolt with the products being joined,One crucial factor to consider. Compatibility between the bolt and the substrate is important to stop deterioration and make sure a protected link. Additionally, the sort of packing and ecological conditions the assembly will be subjected to have to be considered when choosing bolts. Factors such as tensile strength, shear toughness, and resistance to resonance play a crucial role in figuring out the viability of a bolt for a specific application.

Enhancing Precision With Machining Solutions

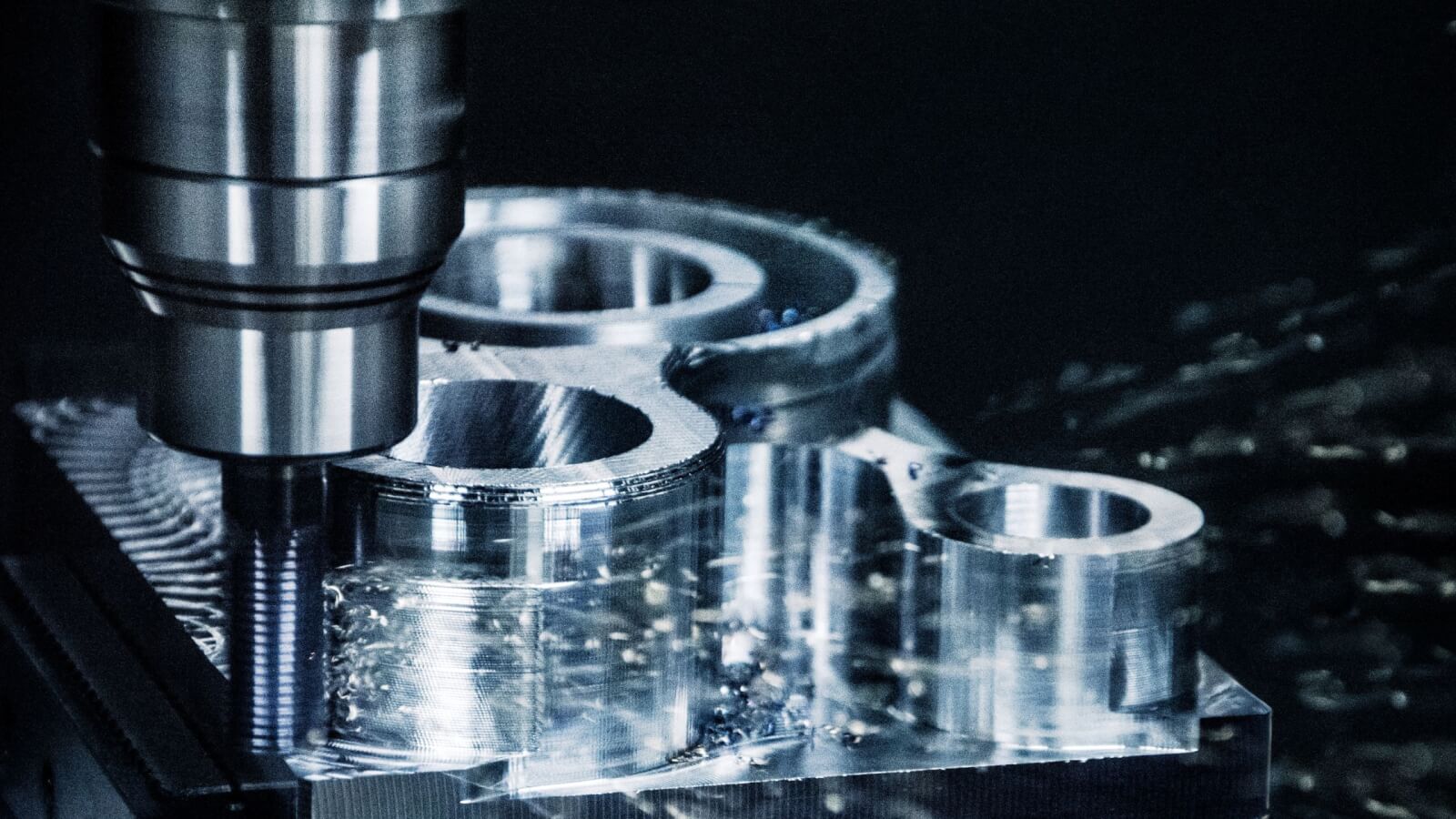

Using innovative machining remedies can substantially improve the accuracy and efficiency of manufacturing procedures. Accuracy in machining is essential for making certain that components meshed effortlessly, reducing the requirement for rework and boosting the overall high quality of the last product. By leveraging innovative machining technologies such as Computer Numerical Control (CNC) devices, producers can attain limited resistances and elaborate layouts easily.

Furthermore, progressed machining remedies supply capabilities such as multi-axis machining, high-speed cutting, and integrated automation, which streamline manufacturing procedures and improve overall precision. These modern technologies make it possible for makers to create intricate get rid of marginal error, resulting in higher performance and cost savings in the future.

Along with accuracy, machining solutions additionally play a crucial function in enhancing consistency across production sets. By setting machining procedures to precise specifications, makers can reproduce the very same high-quality results continuously, guaranteeing harmony in the last products. On the whole, investing in advanced machining remedies is important for makers wanting to elevate their accuracy capabilities and attain seamless operations.

Optimizing Efficiency in Procedures

Enhancing operational effectiveness is extremely important for taking full advantage of efficiency and decreasing prices in producing procedures. By eliminating waste, standardizing processes, and constantly enhancing procedures, firms can enhance their overall effectiveness.

Making use of innovative modern technologies such as automation, robotics, and data analytics can also play a substantial function in optimizing operations (Fasteners and Machining). These technologies can assist reduce hands-on labor, enhance accuracy, and offer real-time insights for better decision-making. Additionally, spending in staff member training and growth can improve ability degrees and make sure that employees are outfitted to take care of jobs successfully

Working together carefully with providers to enhance supply chains and applying just-in-time supply systems can additionally increase efficiency by reducing preparations and reducing excess inventory. On the whole, by concentrating on taking full advantage of efficiency in operations, firms can boost their competition, boost customer fulfillment, and achieve lasting development in the long-term.

Seamless Integration of Bolts and Machinery

To accomplish seamless integration, producers need to thoroughly select fasteners that fulfill the specific demands of the equipment being assembled. Elements such as product compatibility, corrosion, toughness, and dimension resistance are essential factors to consider in picking the ideal bolts. Additionally, making use of innovative machining methods and technologies can better boost the combination process by ensuring specific blog here fitting and placement of bolts within the equipment components.

Effect On Efficiency and Quality

The smooth combination of fasteners and equipment substantially influences both performance and quality in making operations. Fasteners and Machining. By meticulously choosing the right bolts and machining solutions, suppliers can enhance their manufacturing processes, leading to boosted performance and this hyperlink output.

Verdict

In final thought, selecting the proper fasteners and machining solutions is crucial for enhancing and maximizing operations performance. The combination of these components can significantly affect the efficiency and high quality of procedures. By very carefully thinking about the compatibility and accuracy of fasteners and machinery, smooth operations can be accomplished, bring about enhanced total performance and success in numerous industries.

In the detailed landscape of industrial operations, the duty of fasteners and machining options frequently goes undetected, yet their significance in guaranteeing efficient and smooth procedures can not be overemphasized.One key consideration when choosing bolts is to match the product of the fastener with the products being signed up with. Additionally, utilizing sophisticated machining strategies and modern technologies can even more improve the assimilation procedure by making sure precise suitable and positioning of fasteners within the equipment elements.

By very carefully selecting the right bolts and machining services, makers Learn More can improve their production procedures, leading to raised performance and result. Accuracy machining ensures that components are accurately refined, fitting together seamlessly with fasteners for a accurate and trustworthy end item.

Report this page