Getting The Premier Aluminum Llc To Work

Getting The Premier Aluminum Llc To Work

Blog Article

Not known Facts About Premier Aluminum Llc

Table of ContentsNot known Facts About Premier Aluminum LlcThe 10-Second Trick For Premier Aluminum LlcAll about Premier Aluminum LlcThe 7-Minute Rule for Premier Aluminum Llc

(http://prsync.com/premier-aluminum/)Using low expense and unqualified distributors can trigger high quality issues, and wasted time and cash in the long run. To aid you with the process, below are some things to consider when picking the best steel casting provider.

A company that just uses the investment casting process will certainly try to sell you on why that procedure is best for your application (Aluminum Casting). What if using the sand spreading procedure is best for you and your demands? Rather, seek a vendor that provides a variety of casting processes so the finest alternative for YOU is chosen

If dealing with a single source for every one of your casting requires is important to you, the vendor needs to be diverse in its abilities. When integrated with various other incorporated abilities, this can aid simplify and compress the supply base. When picking the ideal spreading distributor, mindful factor to consider needs to be provided to high quality, solution, and cost.

Some Known Facts About Premier Aluminum Llc.

Buyers significantly pick spreading suppliers who have machining abilities. This can avoid problem if problems are uncovered during machining. If a 3rd party is machining, it might result in "finger-pointing" regarding who is at fault. Is it a casting concern or a machining concern? If the casting supplier uncovers a problem during machining, the problem is fixed faster with no conflict over whose mistake it is.

Trouble or no, incorporated machining simplifies the supply chain and reduces dealing with time and delivery cost before the item makes it to the customer. What do you need from your casting provider? Are you seeking a person to just supply a steel component to your front door or do you need much more? For instance, if you do not have internal metallurgy expertise, validate that the supplier can provide support in picking the correct alloy based on your specific application - Aluminum Metal casting.

Some shops are minimal or specialized. Make sure the supplier can satisfy all your material or alloy requirements to get rid of the need for multiple suppliers.

More About Premier Aluminum Llc

Research the supplier's internet site. Speak to a sales rep or business partner. Ask a lot of questions. See their facility. Obtain an understanding of what they can do for you and if you can see yourself constructing a strong, common relationship with them.

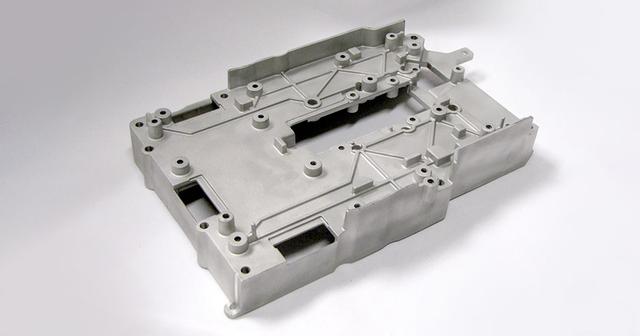

Light weight aluminum is also lightweight and has great corrosion resistance, making it optimal for applications where weight and resilience More Bonuses are very important aspects. Furthermore, aluminum casting is an affordable technique of production, as it needs much less energy and resources than various other approaches. Iron spreading, on the various other hand, entails putting liquified iron into a mold and mildew to develop a wanted shape.

The Single Strategy To Use For Premier Aluminum Llc

Iron casting is additionally able to endure heats, making it ideal for use in applications such as engine parts and commercial machinery. Nevertheless, iron casting can be a lot more costly than light weight aluminum casting due to the higher expense of basic materials and the energy called for to thaw the iron. When making a decision in between light weight aluminum casting and iron casting, it is essential to take into consideration the certain demands of the application.

In final thought, both aluminum casting and iron casting have their own one-of-a-kind advantages and negative aspects. There are three sub-processes that drop under the classification of die casting: gravity pass away casting (or permanent mold and mildew casting), low-pressure die spreading and high-pressure die spreading. To obtain to the ended up product, there are three primary alloys utilized as die casting product to select from: zinc, aluminum and magnesium. Report this page